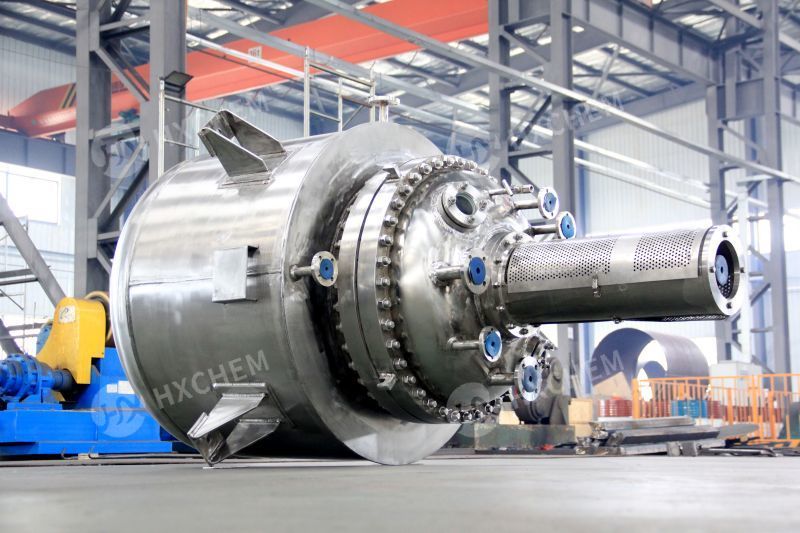

Χημικός αντιδραστήρας 500L από ανοξείδωτο χάλυβα

Χημικός αντιδραστήρας 500L από ανοξείδωτο χάλυβα. Πιλοτικός χημικός αντιδραστήρας; αντιδραστήρας από ανοξείδωτο χάλυβα. SS304 αντιδραστήρας; Χημικός αντιδραστήρας με τζάκετ θέρμανσης. Αναδευόμενος χημικός αντιδραστήρας; 500 λίτρα αντιδραστήρα? 500L χημικός αντιδραστήρας; 500L Αντιδραστήρας πίεσης; Ανοξείδωτος αντιδραστήρας με μόνωση

- HXCHEM

- Κίνα

- 50 ημέρες μετά την πληρωμή

- 40 σετ/μήνα

Λεπτομέριες

500liters ανοξείδωτος ατσάλι χημική ουσία αντιδραστήρας

με θέρμανση σακάκι &αμπέραζ; μόνωση

Εισαγωγή

500L ανοξείδωτος ατσάλι χημική ουσία αντιδραστήρας; 500liters αντιδραστήρας; 500L χημική ουσία αντιδραστήρας; 500L Πίεση αντιδραστήρας; Αυτό σειρά ανοξείδωτος ατσάλι χημική ουσία αντιδραστήρας, σχέδιο όπως και a Άνοιξε τύπος ελλειπτικός κεφάλι με μπουλόνια φλάντζα κλείσιμο, εξοπλισμένο με διπλό τέλος μηχανικός σφραγίδα έργα κάτω από βέβαιος πίεση και θερμοκρασία; ο αντιδραστήρας σώμα θερμός με γεμάτος σακάκι και μόνωση εξωτερικός. ο ειδικός δεδομένα βλέπω ΕΠΟΜΕΝΟ:

Μπλουζα ελλειπτικός κεφάλι με φλάντζα βάση;

Ενταση ΗΧΟΥ: 600liters

Ανώτατο όριο Πίεση: -1 (FV) προς την +4 μπαρ;

Ανώτατο όριο Θερμοκρασία: -100 °C προς την +100 °C;

Υλικό:SS304, SS316, Hastelloy C276, Νικέλιο, Τιτάνιο, Ζιρκόνιο, και τα λοιπά;

Θέρμανση σακάκι: Συμβατικός Σακάκι

Εσωτερικός ψύξη πηνία:2.2m2 ψύξη περιοχή

Σφραγίδα τύπος:Μηχανικός σφραγίδα

Ταραχοποιός:4KW, Δύο στάδιο Κουπί,0-120rpm

Προαιρετικός

Λάδι κυκλοφορώ σακάκι θέρμανση; Ατμός θέρμανση;

Ανυψωτήρας Για αντιδραστήρας κεφάλι (εγχειρίδιο ή ηλεκτρικός επιλογές);

Κάτω μέρος διοχετεύω βαλβίδα ;

Μόνωση σακάκι;

Ασφάλεια βαλβίδα;

Μπλουζα Κλείσε τύπος ή Μπλουζα Άνοιξε τύπος;

Μπλουζα κεφάλι τύπος: Διαμέρισμα κεφάλι; Ελλειπτικός φλάντζα κεφάλι;

GSH πιλότος πίεση αντιδραστήρας πρότυπο προσδιορισμός

| GSH-50 | ||||

| 50 | ||||

Πρότυπο 100bar, -0.1-250 μπαρ προσαρμοσμένη | ||||

SS304 ή SS316 βρεγμένο εξαρτήματα, άλλα κράματα (Τιτάνιο, Hastelloy, Διπλός ατσάλι, και τα λοιπά.) | ||||

0~350 προσαρμόστε με βάση επί λειτουργεί θερμοκρασία. | ||||

| 0-500 | ||||

| 1.5 | ||||

Σύμφωνα με προς την ο εργαζόμενος θερμοκρασία | ||||

Πρότυπο ηλεκτρικός θέρμανση(Θερμικός λάδι, ατμός, μακριά υπέρυθρες θέρμανση διαθέσιμος) | ||||

Διαμέρισμα κάλυμμα ή ελλειπτικός φλάντζα κλείσιμο | ||||

Προπέλα, κουπί, άγκυρα, σπειροειδής, τουρμπίνα, αέριο προκαλώντας τύπος, και τα λοιπά | ||||

Σπειροειδής ψύξη δροσίζει με ψύξη νερό | ||||

Εκφόρτιση από κάτω μέρος ή πάνω από. | ||||

PID θερμοκρασία απεικόνιση και έλεγχος, ακρίβεια±1 ℃; Ανακάτεμα Ταχύτητα απεικόνιση; Λειτουργία χρόνος απεικόνιση; Θέρμανση Τάση και ρεύμα απεικόνιση; Αφή οθόνη προαιρετικός. | ||||

Πίεση μετρητής, Ασφάλεια βαλβίδα Λιμάνι; Θερμ. μέτρημα Λιμάνι; Αέριο και υγρό Λιμάνι; Βουτιά σωλήνας; Διέξοδος Λιμάνι; Στερεός φόρτιση Λιμάνι; Ψύξη σπείρα είσοδος και εξωτερικός Λιμάνι; | ||||

Σημείωση:ο πάνω από πρότυπο Παράμετροι είναι Για αναφορά μόνο. Διαφορετικός διαδικασία έχω δικα τους τα δικά λογικός επιλογή, δεν ο περισσότερο πλήρης ο λειτουργία, ο καλύτερα.

ο δομή, προσδιορισμός, στόμιο Μέγεθος και προσανατολισμός χρειάζομαι προς την είναι επιβεβαιώθηκε μετά επικοινωνώντας με μας.